INNOTEC Premium Silicone Sealant "Easy Seal XS" - 310ml Cartridge

Customer service

Customer service

Do you have questions about our products, need help with your order or just want a quick answer?

We are happy to be available to you personally – by email, telephone, WhatsApp or directly via our chat.

- Frequently asked questions

On this page we explain many topics - servus@mikestoolshop.at

for emails - +43627893080

for call or WhatsApp - about the shop

Simply click on the chat icon at the bottom right of every page.

Monday to Thursday: 8am–4pm, Friday: 8am–3pm.

We look forward to hearing from you!

Shipping & Delivery

Shipping & Delivery

Orders for products in stock that reach us by 1:30 p.m. are usually dispatched on the same working day.

In our warehouse in Ostermiething, with over 8,000 storage spaces, we keep many items immediately available. Should something go missing, we'll be happy to source it for you directly from the manufacturer.

We package your order securely and robustly, and you always receive tracking information.

Want to know all the details about shipping and delivery? Click here!

Verfügbare Downloads

3_EasySealXS310mlAnthracite_1017_de.pdf

3_EasySealXS310mlBeige_Bahama__1016_de.pdf

3_EasySealXS310mlBlack_1025_de.pdf

3_EasySealXS310mlLightGrey_1023_de.pdf

3_EasySealXS310mlOpaque_1021_de.pdf

3_EasySealXS310mlPergamon_1018_de.pdf

3_EasySealXS310mlStainlessSteel_1024_de.pdf

3_EasySealXS310mlTransparentGrey_1020_de.pdf

3_EasySealXS310mlSilverGrey_1019_de.pdf

Description

Description

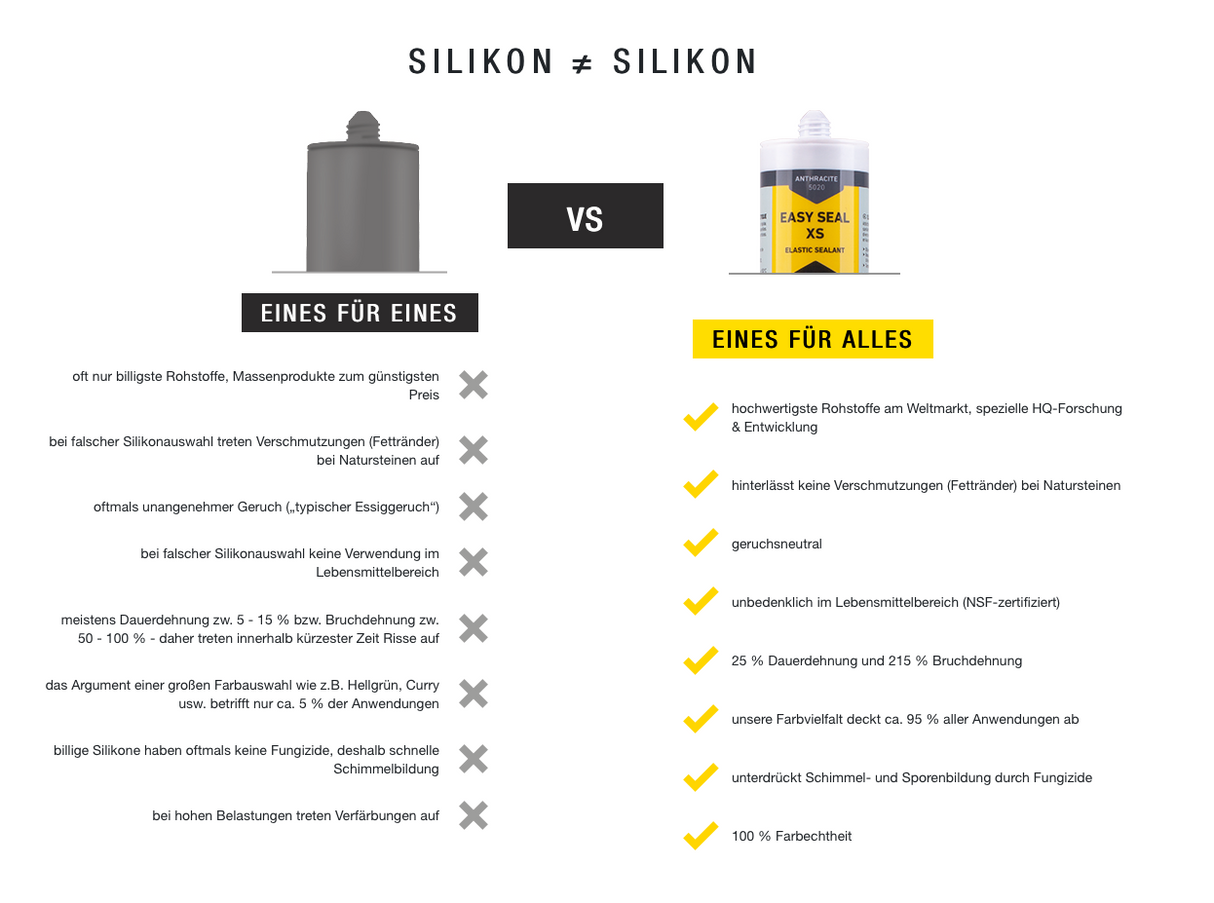

Easy Seal XS. One for all.

Easy Seal XS is a unique, neutral-curing, acid-, solvent- and oxime-free premium silicone sealant based on odorless alkoxy polysiloxanes for the secure and permanently elastic sealing of various construction and connection joints on a wide variety of substrates.

HIGHLIGHTS

- Absolutely harmless and odorless

- Acid-, solvent- and oxime-free

- High UV and temperature resistance (-40 °C to +150 °C)

- 100% colorfastness - no discoloration or yellowing

- Excellent water resistance and mold resistance

- Permanently elastic (215% elongation at break)

- NSF-certified, cleanroom compatible, chlorine, salt water and lactic acid resistant

- Certified with the GEV-Emicode EC1-Plus - very low emissions

THE BEST “SILICONE” YOU’VE EVER HAD.

- Acid-, solvent- and oxime-free, therefore absolutely harmless to health and odorless

- Can also be used on sensitive surfaces without any problems - no joint or edge soiling (e.g. marble, granite)

- Does not attack films and coatings on laminated glass and mirrors

- No shrinkage, cracking or collapse

- Has a CE marking, which complies with all uniformly applicable rules of the EU Construction Products Regulation (the detailed declaration of performance can be found at www.innotec.at)

- Very high UV resistance and particularly high temperature resistance (-40 °C to +150 °C)

- 100% colorfastness - no more annoying discoloration and yellowing

- Excellent water resistance - does not absorb water or moisture, therefore particularly suitable for all wet areas - no mold formation

- Good salt water resistance

- Ideal for use in and around water basins

- Permanently elastic (215% elongation at break, 100% recovery, 25% permanent elongation)

- Optimal adhesion on almost any surface - countless areas of application

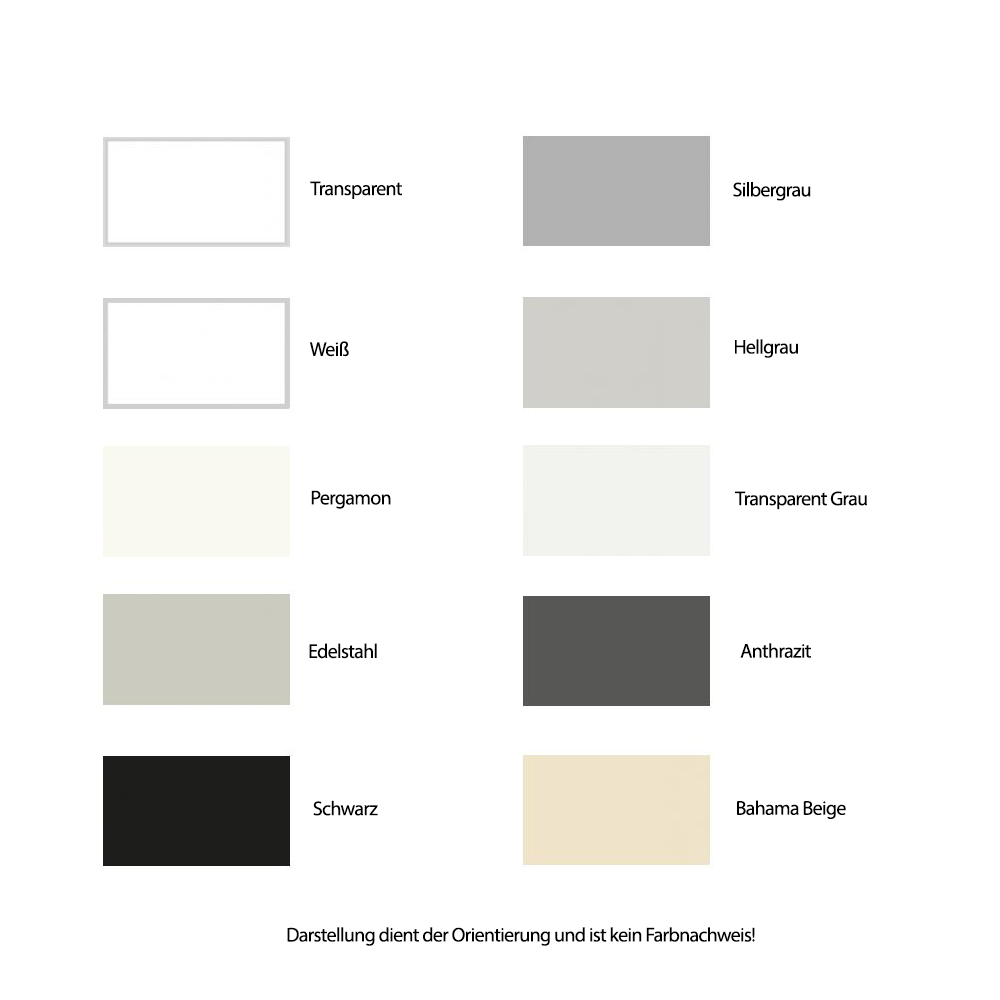

- “Chameleon effect” with colour code Transparent (Opaque) - jointing is hardly noticeable

- Easy and quick to apply - fast skin formation

- Repair possible within approx. 10 minutes - if the sealing bead is damaged, it can be repaired

APPLICATION

APPLICATIONS AUTOMOTIVE INDUSTRY

- For jointing aluminum and stainless steel sheets in vehicle bodies (specially developed metallic gray)

- For subsequent sealing of e.g. silver / grey painted vehicles (specially developed metallic grey)

APPLICATIONS INDUSTRY

- Marble, granite, natural stone, concrete, ceramic and enamel tiles, wood, metal, sheet metal (galvanized and powder-coated), aluminum, stainless steel, glass (also ideal for laminated glass), mirrors, numerous plastics (e.g. windows, doors, acrylic-coated bathtubs and shower trays) and much more

- Also ideal for kitchens, window sills, tiled stoves, outdoor pools, indoor pools (good chlorine resistance), swimming pool roofs, conservatories, glass facades, skylights, roof connections, saunas, steam baths, wellness areas, etc.

PROCESSING

NOTES

- Calculation formula for the maximum joint depth and width: The maximum joint depth is one-third of the joint width plus 6 millimeters:

T (max. joint depth) = B (joint width / 3) + 6 mm - Pretreatment of the substrate

To clean the surfaces to be sealed, use Innotec Seal and Bond Remover (Art. No. 1270) or Innotec Multisol (Art. No. 124). Apply the solvent to a clean cloth or directly to the substrate. To allow the solvent to evaporate properly, always wipe dry. If there are any silicone residues on the substrate, spray them with Seal and Bond Remover and allow them to react for approximately 4 to 6 minutes to completely remove them. For heavier residues, repeat this process several times. - Sealing on special substrates

For sealing on special surfaces (such as powder-coated sheet metal, acrylic coatings, and absorbent substrates), these must be pretreated with Seal Guard (Art. No. 1487) to ensure optimal adhesion. Apply Seal Guard with a soft brush/wool mop (Art. No. 1480) and apply Easy Seal XS within 10 minutes to 4 hours. - Application in swimming pools / water basins

Ensure the surface is clean, dry, and free of grease. Always prime joints with a suitable primer (Seal Guard). If necessary, apply Innotec Back Fill Foam to precisely size the joint and/or prevent three-point adhesion.

Before refilling the pool, Easy Seal XS must be completely dry (ideally at least 4 days)!

Due to the variety of different additives used for water treatment, the service life of Easy Seal XS when used in swimming pools/water basins cannot be clearly specified! - Easy Seal XS processing

Apply Easy Seal XS directly using the Easy Grip Gun cartridge gun (item no. 1490-1).

To smooth the sealing bead, Seal Fluid (Art. No. 1274) should be used. Apply Seal Fluid directly onto the sealing bead and the

Spray the smoothing tool and smooth the bead. Once the sealing bead has sufficiently cured, remove any excess Seal Fluid with water and a clean cloth.

Caution: When smoothing with Seal Fluid on natural stone, slight discoloration may occur! - cleaning

To remove excess Easy Seal XS from the surface and tools, it is best to use Innotec Seal and Bond Remover (Art. No. 1270) or Innotec Ultra Clean (Art. No. 121)

DOWNLOAD

TECHNICAL DATA

- Base Alcoxy

- Density approx. 1010 kg/m3

- Consistency Pasty

- Solvents None

- Hardness approx. 25 (Shore A)

- Breaking strength (tensile strength) approx. 0.52 N/mm2 (according to DIN 53504)

- Elongation at break (%) approx. 215% (according to DIN 53504)

- Modulus approx. 0.36 N/mm2 (at 100% elongation) (according to DIN 53504)

- Shear strength 0.6 N/mm2 (according to DIN 53283)

- Recovery capacity approx. 100%

- Temperature resistance -40 °C to +150 °C

- UV resistance Very Good

- Water resistance Very Good

- Solvent resistance Good, resistant to various solvents

- Fungal resistance very good

- Good stamina

- Tests Meets NSF requirements for Category R2, Registration Number: 143799

- Processing conditions +5 °C to +30 °C

- Skin formation after approx. 10 minutes (at 23 °C / 50 % relative humidity)

- Touch dry after 60 minutes (at 23 °C / 50 % relative humidity)

- Curing time: approx. 2 mm in 24 hours (at 23 °C / 50 % relative humidity)

- Minimum joint width 4 mm

- Maximum joint width 20 mm

- Permanent elongation 20%

- Not paintable

- Shelf life 1 year in unopened original packaging. Store in a cool, dry place.

- Details Due to the constantly changing water quality in swimming pools and water basins, the service life of Easy Seal XS when used in swimming pools/water basins cannot be clearly stated. OEM approval

- CE Certification Easy Seal XS is a CE-marked product in accordance with Regulation (EU) No. 305/2011: CE EN 15651-1:2012, F INT-EXT 20LM CE EN 15651-3:2012, XS1 You can download the corresponding Declaration of Performance (DoP No. 0114530100) from our website <- here.

PAYMENT & SECURE SHOPPING

Our payment methods

We offer a variety of established and trusted payment methods for your order. If you need further confirmation, you can always call us by phone or WhatsApp.

To the contact page

Matching accessories

- -