SAFE TABLE SAWS

Sawstop works in under 5 milliseconds!

An airbag in a car takes 20-30 milliseconds

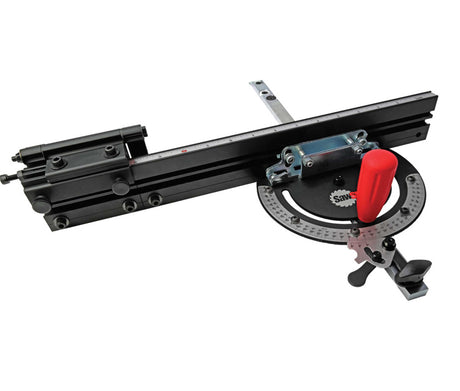

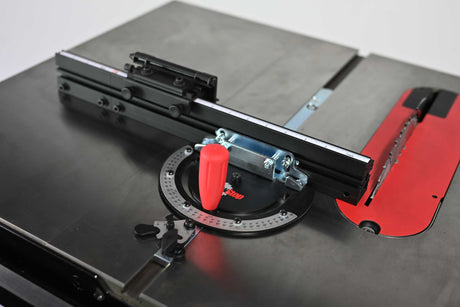

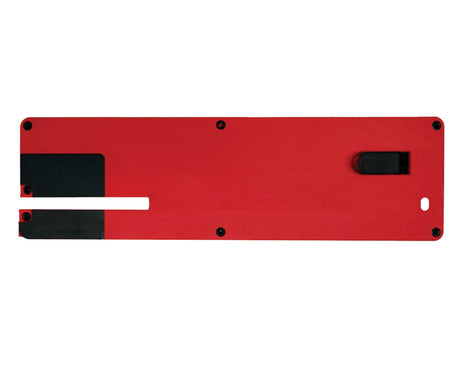

Matching accessories

FREQUENTLY ASKED QUESTIONS

How does the SawStop safety system work?

How does the SawStop safety system work?

SawStop detects contact between skin and the sawblade in just a few milliseconds via an electrical signal. As soon as human skin is detected, an aluminum brake block releases the sawblade within 5 milliseconds – the blade instantly dives under the table and stops. This can prevent a serious accident.

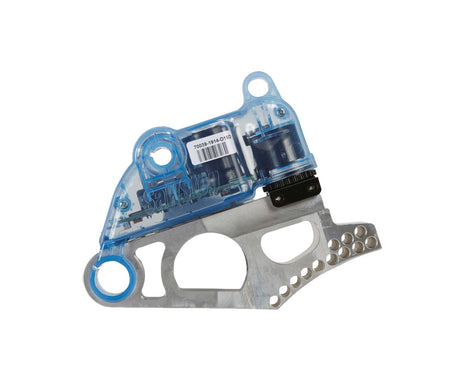

Does the entire system need to be replaced after a trigger?

Does the entire system need to be replaced after a trigger?

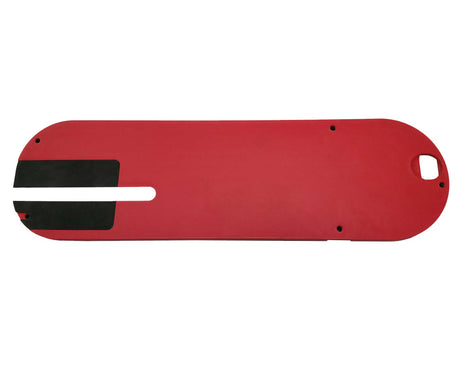

No. After a triggering, only the saw blade brake (brake cartridge) and the damaged saw blade need to be replaced. The saw itself remains undamaged. The replacement parts can be replaced quickly and easily.

How reliable is the system in everyday use?

How reliable is the system in everyday use?

SawStop has been on the market for over 20 years and is used worldwide by professionals, training centers, and hobbyists. The technology is sophisticated, low-maintenance, and operates flawlessly under normal conditions – even with damp wood or antistatic dust. False triggers are extremely rare.

Can the security feature be deactivated?

Can the security feature be deactivated?

Yes, the system can be manually deactivated for certain operations (e.g., when cutting highly conductive materials such as very wet wood or metal, or during testing). SawStop detects this and clearly indicates that the protection is not active.

What should be checked or maintained regularly?

What should be checked or maintained regularly?

In addition to general machine maintenance (dust extraction, saw blade care, etc.), the brake cartridge should be visually inspected regularly and replaced after approximately two years (depending on frequency of use). An occasional self-test via the control panel is also recommended.

Is SawStop compatible with standard saw blades?

Is SawStop compatible with standard saw blades?

Yes, standard 254 mm circular saw blades with a standard bore can be used. It's important that the saw blade matches the machine and the material—for example, blades that are too thick or too thin should not be used, as this may prevent the system from triggering correctly.